ABOUT US

ERJOT was established in 1987. We have been steadily developing our machine stock and production capacity since then. The result of this growth is a production plant with about 20 employees. We have an extensive machine stock with 6 vertical and 3 horizontal CNC machining centres, 7 CNC lathes, grinders, a thread roller, etc, which allows to process most orders in machining. We have experienced managers and employees of high occupational qualifications. Our activities feature timely work and high quality of the completed goods. To increase certainty of clients as regards the orders completed by us, we have implemented the ISO 9001:2015 quality management system.

For 20 years of operations, we have developed good contact with many partners. These are: grey cast iron, spheroidal cast iron, and cast steel foundries, drop forging shops, hardening shops, tool shops, and other. We also cooperate with various suppliers of finished components, including bearings, rubber elements, and plastic items. A broad range of contacts allows us to manufacture not only elements done on our machine tools, but also complex components and finished market-ready products.

Offer

Check our offer.

CNC turning with centre lathes

CNC turning with chuck lathes

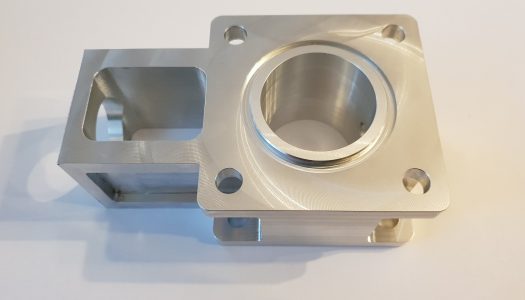

CNC milling with 3, 4 and 5 axis vertical and horizontal CNC machining centres

Surface grinding

Cylindrical grinding

Internal grinding

Fellows gear shaping

Gear hobbing

Horizontal milling

Milling with universal milling machines

Turning with conventional lathes

Roll threading

MACHINE STOCK

Our machine stock includes:

|

|

QUALITY POLICY

High quality of products and services that we provide is the priority in the operations of PPH ERJOT. This directly translates to the perception of the company by our clients and strengthens positive image and prestige.

The implementation and using of the quality management system based on the EN ISO 9001:2015 standard consolidates the basic principle of operations of the company that consists in providing services, production and sale of goods of repeatable and guaranteed quality, as expected by our recipients.

The functioning quality management system obliges all the employees of the company to reliably perform work, ensuring high quality of products and services and timely completion of orders.

Enhancing professional qualifications, improvement of the management system, implementation of new and rationalisation of the existing technical solutions, improving the quality of the products and services with the simultaneous minimisation of the operating costs is in particular the task of the technical supervision, but also other employees and continuous care of the Owner of the company.

GALLERY

Browse our gallery.